起点亦是终点,世间有轮回,相似又不相同。就像书里写的那样。江湖因一声“小二上酒”开始,最后也因一杯绿蚁戛然而止。生活,也是如此吧?

飞控不是一下做出来的,下面是一些重要传感器的mpy驱动代码,为飞控项目添砖加瓦。

from pyb import Pinfrom time import sleep_us,ticks_usclass HC():def __init__(self,trig='C5',echo='C4'):self.trig = Pin(trig, Pin.OUT_PP)self.echo = Pin(echo, Pin.IN)def trigUp(self):self.trig.value(1)sleep_us(25)self.trig.value(0)def getlen(self):distance = 0self.trigUp()while self.echo.value() == 0:passts = ticks_us() # 开始时间while self.echo.value() == 1:passte = ticks_us() # 结束时间tc = te - ts # 回响时间(单位us)distance = (tc * 170) / 10000 # 距离计算(单位为:cm)return distance

超声波传感器

'''参考:https://blog.csdn.net/qq_38721302/article/details/83095545'''MPU_ADDR=0X68WHO_AM_I_VAL = MPU_ADDRMPU_PWR_MGMT1_REG = 0x6B # 电源管理寄存器1MPU_GYRO_CFG_REG = 0X1B # 陀螺仪配置寄存器MPU_ACCEL_CFG_REG = 0X1C # 加速度传感器配置寄存器MPU_SAMPLE_RATE_REG=0X19 # 设置MPU6050的采样率MPU_CFG_REG=0X1A # 配置寄存器MPU_INT_EN_REG=0X38MPU_USER_CTRL_REG=0X6AMPU_FIFO_EN_REG=0X23MPU_INTBP_CFG_REG=0X37MPU_DEVICE_ID_REG=0X75MPU_GYRO_XOUTH_REG=0X43MPU_GYRO_XOUTL_REG=0X44MPU_GYRO_YOUTH_REG=0X45MPU_GYRO_YOUTL_REG=0X46MPU_GYRO_ZOUTH_REG=0X47MPU_GYRO_ZOUTL_REG=0X48MPU_ACCEL_XOUTH_REG=0X3BMPU_ACCEL_XOUTL_REG=0X3CMPU_ACCEL_YOUTH_REG=0X3DMPU_ACCEL_YOUTL_REG=0X3EMPU_ACCEL_ZOUTH_REG=0X3FMPU_ACCEL_ZOUTL_REG=0X40MPU_TEMP_OUTH_REG=0X41MPU_TEMP_OUTL_REG=0X42config_gyro_range = 3 # 0,±250°/S;1,±500°/S;2,±1000°/S;3,±2000°/Sconfig_accel_range = 0# 0,±2g;1,±4g;2,±8g;3,±16gclass MPU6050():def __init__(self,iicbus,address=WHO_AM_I_VAL):self._address = addressself._bus = iicbusself.reset()def _write_byte(self,cmd,val):self._bus.mem_write(val,self._address,cmd)def _read_byte(self,cmd):buf = self._bus.mem_read(1,self._address,cmd,addr_size=8)return int(buf[0])def reset(self):self._write_byte(MPU_PWR_MGMT1_REG, 0x00) # 配置电源管理寄存器 启动MPU6050self._write_byte(MPU_GYRO_CFG_REG, config_gyro_range<<3) # 陀螺仪传感器,±2000dpsself._write_byte(MPU_ACCEL_CFG_REG, config_accel_range<<3)# 加速度传感器,±2gself._write_byte(MPU_SAMPLE_RATE_REG, 0x07) # 采样频率 100self._write_byte(MPU_CFG_REG, 0x06) # 设置数字低通滤波器self._write_byte(MPU_INT_EN_REG,0X00) #关闭所有中断self._write_byte(MPU_USER_CTRL_REG,0X00) #I2C主模式关闭self._write_byte(MPU_FIFO_EN_REG,0X00) #关闭FIFOself._write_byte(MPU_INTBP_CFG_REG,0X80) #INT引脚低电平有效buf = self._read_byte(MPU_DEVICE_ID_REG)if buf != self._address:print("NPU6050 not found!")else:passdef _read_byte(self,cmd):buf = self._bus.mem_read(1,self._address,cmd,addr_size=8)return int(buf[0])def _read_u16(self,reg):MSB = self._read_byte(reg)LSB = self._read_byte(reg)return (MSB<< 8) + LSBdef _read_s16(self,reg):result = self._read_u16(reg)if result > 32767:result -= 65536return resultdef read_Gyro_x(self):x = self._read_s16(MPU_GYRO_XOUTH_REG)return xdef read_Gyro_y(self):y = self._read_s16(MPU_GYRO_YOUTH_REG)return ydef read_Gyro_z(self):z = self._read_s16(MPU_GYRO_ZOUTH_REG)return zdef read_Accel_x(self):x = self._read_s16(MPU_ACCEL_XOUTH_REG)return xdef read_Accel_y(self):y = self._read_s16(MPU_ACCEL_YOUTH_REG)return ydef read_Accel_z(self):z = self._read_s16(MPU_ACCEL_ZOUTH_REG)return zdef read_Temp(self):temp = self._read_s16(MPU_TEMP_OUTH_REG)return tempfrom pyb import I2Ci2c = I2C(2, I2C.MASTER)mpu = MPU6050(i2c)def GyroToDegree(num):return num / 32768 * 2000def AccelToGram(num):return num / 32768 * 2

MPU6050

from imu import InvenSenseMPU, bytes_toint, MPUExceptionfrom imu import Vector3dclass MPU9250(InvenSenseMPU):'''MPU9250 constructor arguments1. side_str 'X' or 'Y' depending on the Pyboard I2C interface being used2. optional device_addr 0, 1 depending on the voltage applied to pin AD0 (Drotek default is 1)if None driver will scan for a device (if one device only is on bus)3, 4. transposition, scaling optional 3-tuples allowing for outputs to be based on vehiclecoordinates rather than those of the sensor itself. See readme.'''_mpu_addr = (104, 105) # addresses of MPU9250 determined by voltage on pin AD0_mag_addr = 12 # Magnetometer address_chip_id = 113def __init__(self, side_str, device_addr=None, transposition=(0, 1, 2), scaling=(1, 1, 1)):super().__init__(side_str, device_addr, transposition, scaling)self._mag = Vector3d(transposition, scaling, self._mag_callback)self.accel_filter_range = 0 # fast filtered responseself.gyro_filter_range = 0self._mag_stale_count = 0 # MPU9250 count of consecutive reads where old data was returnedself.mag_correction = self._magsetup() # 16 bit, 100Hz update.Return correction factors.self._mag_callback() # Seems neccessary to kick the mag off else 1st reading is zero (?)def sensors(self):'''returns sensor objects accel, gyro and mag'''return self._accel, self._gyro, self._mag# get temperaturedef temperature(self):'''Returns the temperature in degree C.'''try:self._read(self.buf2, 0x41, self.mpu_addr)except OSError:raise MPUException(self._I2Cerror)return bytes_toint(self.buf2[0], self.buf2[1])/333.87 + 21 # I think# Low pass filtersdef gyro_filter_range(self):'''Returns the gyro and temperature sensor low pass filter cutoff frequencyPass: 0 1 2 3 4 5 6 7Cutoff (Hz): 250 184 92 41 20 10 5 3600Sample rate (KHz): 8 1 1 1 1 1 1 8'''try:self._read(self.buf1, 0x1A, self.mpu_addr)res = self.buf1[0] & 7except OSError:raise MPUException(self._I2Cerror)return resdef gyro_filter_range(self, filt):'''Sets the gyro and temperature sensor low pass filter cutoff frequencyPass: 0 1 2 3 4 5 6 7Cutoff (Hz): 250 184 92 41 20 10 5 3600Sample rate (KHz): 8 1 1 1 1 1 1 8'''if filt in range(8):try:self._write(filt, 0x1A, self.mpu_addr)except OSError:raise MPUException(self._I2Cerror)else:raise ValueError('Filter coefficient must be between 0 and 7')def accel_filter_range(self):'''Returns the accel low pass filter cutoff frequencyPass: 0 1 2 3 4 5 6 7 BEWARE 7 doesn't work on device I tried.Cutoff (Hz): 460 184 92 41 20 10 5 460Sample rate (KHz): 1 1 1 1 1 1 1 1'''try:self._read(self.buf1, 0x1D, self.mpu_addr)res = self.buf1[0] & 7except OSError:raise MPUException(self._I2Cerror)return resdef accel_filter_range(self, filt):'''Sets the accel low pass filter cutoff frequencyPass: 0 1 2 3 4 5 6 7 BEWARE 7 doesn't work on device I tried.Cutoff (Hz): 460 184 92 41 20 10 5 460Sample rate (KHz): 1 1 1 1 1 1 1 1'''if filt in range(8):try:self._write(filt, 0x1D, self.mpu_addr)except OSError:raise MPUException(self._I2Cerror)else:raise ValueError('Filter coefficient must be between 0 and 7')def _magsetup(self): # mode 2 100Hz continuous reads, 16 bit'''Magnetometer initialisation: use 16 bit continuous mode.Mode 1 is 8Hz mode 2 is 100Hz repetitionreturns correction values'''try:self._write(0x0F, 0x0A, self._mag_addr) # fuse ROM access modeself._read(self.buf3, 0x10, self._mag_addr) # Correction valuesself._write(0, 0x0A, self._mag_addr) # Power down mode (AK8963 manual 6.4.6)self._write(0x16, 0x0A, self._mag_addr) # 16 bit (0.15uT/LSB not 0.015), mode 2except OSError:raise MPUException(self._I2Cerror)mag_x = (0.5*(self.buf3[0] - 128))/128 + 1mag_y = (0.5*(self.buf3[1] - 128))/128 + 1mag_z = (0.5*(self.buf3[2] - 128))/128 + 1return (mag_x, mag_y, mag_z)def mag(self):'''Magnetomerte object'''return self._magdef _mag_callback(self):'''Update magnetometer Vector3d object (if data available)'''try: # If read fails, returns last valid data andself._read(self.buf1, 0x02, self._mag_addr) # increments mag_stale_countif self.buf1[0] & 1 == 0:return self._mag # Data not ready: return last valueself._read(self.buf6, 0x03, self._mag_addr)self._read(self.buf1, 0x09, self._mag_addr)except OSError:raise MPUException(self._I2Cerror)if self.buf1[0] & 0x08 > 0: # An overflow has occurredself._mag_stale_count += 1 # Error conditions retain last good valuereturn # user should check for ever increasing stale_countsself._mag._ivector[1] = bytes_toint(self.buf6[1], self.buf6[0]) # Note axis twiddling and little endianself._mag._ivector[0] = bytes_toint(self.buf6[3], self.buf6[2])self._mag._ivector[2] = -bytes_toint(self.buf6[5], self.buf6[4])scale = 0.15 # scale is 0.15uT/LSBself._mag._vector[0] = self._mag._ivector[0]*self.mag_correction[0]*scaleself._mag._vector[1] = self._mag._ivector[1]*self.mag_correction[1]*scaleself._mag._vector[2] = self._mag._ivector[2]*self.mag_correction[2]*scaleself._mag_stale_count = 0def mag_stale_count(self):'''Number of consecutive times where old data was returned'''return self._mag_stale_countdef get_mag_irq(self):'''Uncorrected values because floating point uses heap'''self._read(self.buf1, 0x02, self._mag_addr)if self.buf1[0] == 1: # Data is readyself._read(self.buf6, 0x03, self._mag_addr)self._read(self.buf1, 0x09, self._mag_addr) # Mandatory status2 readself._mag._ivector[1] = 0if self.buf1[0] & 0x08 == 0: # No overflow has occurredself._mag._ivector[1] = bytes_toint(self.buf6[1], self.buf6[0])self._mag._ivector[0] = bytes_toint(self.buf6[3], self.buf6[2])self._mag._ivector[2] = -bytes_toint(self.buf6[5], self.buf6[4])

MPU9250

I2C接线图

使用MPU6050 Yaw轴会不可避免的飘动,MPU9250自带磁力计,可以减少飘动。

# 控制电机函数from pyb import Timer,Pin,ADCimport timeclass Motor():# 电机pwm初始化def __init__(self,isInit=False):timerMotor_1 = Timer(3, freq=50)timerMotor_2 = Timer(4, freq=50)self.motor1 = timerMotor_1.channel(1, Timer.PWM, pin=Pin('B4'))self.motor2 = timerMotor_1.channel(2, Timer.PWM, pin=Pin('B5'))self.motor3 = timerMotor_2.channel(3, Timer.PWM, pin=Pin('B8'))self.motor4 = timerMotor_2.channel(4, Timer.PWM, pin=Pin('B9'))self.motors = [self.motor1,self.motor2,self.motor3,self.motor4]# self.x = ADC(Pin('X2'))# self.btn_stop = Pin('X4',Pin.IN)if not isInit:for moto in self.motors:self.MotoSet(moto)time.sleep(1)self.MotosPwmUpdate([0,0,0,0])# 电机初始化 设置最高油门和最低油门def MotoSet(self,moto):moto.pulse_width_percent(10)time.sleep(2)moto.pulse_width_percent(5)# pwm 更新函数 1# 可以用于调试单个电机def MotoPwmUpdate(self,n,pwm):if pwm < 0 or pwm > 100:return Noneself.motors[n].pulse_width_percent(5 + pwm*5/100)# pwm 更新函数 2# 用于实际飞行def MotosPwmUpdate(self,pwms):for moto,pwm in zip(self.motors,pwms):moto.pulse_width_percent(5 + pwm*5/100)# 电机停止转动# 用于紧急制动和测试def MotoStop(self):for moto in self.motors:moto.pulse_width_percent(5)

电调控制,PWM实现

然后就是PWM的接收机太费引脚,换PPM,问题在于转换~

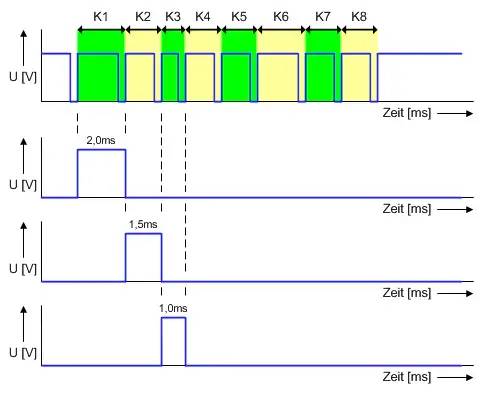

上面是PPM

下面是PWM

标准的PPM信号,以0.4ms的低电平为起始标识。后边以电平的上升沿的间隔时间来表达各个通道的控制量。一般排列10个上升沿后,电平保持高电平,直到重复下一个PPM信号。

PPM信号可以看做是一帧数据,它包含了8个通道的信息。每个上升沿间隔时间刚好等于PWM信号的高电平持续时间,也就1000us~2000us之间。

PPM的重复周期也为20ms,也是50hz的刷新频率。

import pybimport micropythonmicropython.alloc_emergency_exception_buf(100)# Futaba PPM decoder# http://diydrones.com/profiles/blogs/705844:BlogPost:38393class Decoder():def __init__(self, pin: str):self.pin = pinself.current_channel = -1self.channels = [0] * 20 # up to 10 channelsself.timer = pyb.Timer(2, prescaler=83, period=0x3fffffff)self.timer.counter(0)# clear any previously set interruptpyb.ExtInt(pin, pyb.ExtInt.IRQ_RISING, pyb.Pin.PULL_NONE, None)self.ext_int = pyb.ExtInt(pin, pyb.ExtInt.IRQ_RISING, pyb.Pin.PULL_NONE, self._callback)def _callback(self, t):ticks = self.timer.counter()if ticks > 5000:self.current_channel = 0elif self.current_channel > -1:self.channels[self.current_channel] = ticksself.current_channel += 1self.timer.counter(0)def get_channel_value(self, channel: int) -> int:return self.channels[channel]def enable(self):self.ext_int.enable()def disable(self):self.ext_int.disable()

PPM驱动代码

# 匿名上位机 移植上位机、协议版本v4.34# 移植部分功能# 关闭了数据的校验功能,提高发送速度class ANO():def __init__(self,uart):self.writechar = uart.writecharself.BYTE0 = lambda x : (x0)&0xffself.BYTE1 = lambda x : (x8)&0xffself.BYTE2 = lambda x : (x16)&0xffself.BYTE3 = lambda x : (x24)&0xffpass# 发送数据def ANO_Send_Data(self,data):for v in data:self.writechar(v)#send 数据def cs(self,data_to_send):_cnt = len(data_to_send)data_to_send[3] = _cnt - 4data_to_send.append(0) # 需要校验功能的将这一行改了就行self.ANO_Send_Data(data_to_send)# 飞机姿态 高度 飞行模式 是否解锁def ANO_DT_Send_Status(self,angle_rol, angle_pit, angle_yaw, alt, fly_model, armed):_cnt = 0_temp = 0_temp2 = altdata_to_send = []data_to_send.append(0xAA)data_to_send.append(0xAA)data_to_send.append(0x01)data_to_send.append(0)_temp = int(angle_rol * 100)data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = int(angle_pit * 100)data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = int(angle_yaw * 100)data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))data_to_send.append(self.BYTE3(_temp2))data_to_send.append(self.BYTE2(_temp2))data_to_send.append(self.BYTE1(_temp2))data_to_send.append(self.BYTE0(_temp2))data_to_send.append(fly_model)data_to_send.append(armed)self.cs(data_to_send)# PID信息def ANO_DT_Send_PID(self,group, p1_p, p1_i, p1_d, p2_p, p2_i, p2_d, p3_p, p3_i, p3_d):_cnt = 0_temp = 0data_to_send = []data_to_send.append(0xAA)data_to_send.append(0xAA)data_to_send.append(0x10 + group -1)data_to_send.append(0)_temp = p1_p * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p1_i * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p1_d * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p2_p * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p2_i * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p2_d * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p3_p * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p3_i * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = p3_d * 1000data_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))self.cs(data_to_send)# 传感器数据def ANO_DT_Send_Senser(self,a_x, a_y, a_z, g_x, g_y, g_z, m_x, m_y, m_z):_cnt = 0_temp = 0data_to_send = []data_to_send.append(0xAA)data_to_send.append(0xAA)data_to_send.append(0x02)data_to_send.append(0)_temp = a_xdata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = a_ydata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = a_zdata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = g_xdata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = g_ydata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = g_zdata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = m_xdata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = m_ydata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))_temp = m_zdata_to_send.append(self.BYTE1(_temp))data_to_send.append(self.BYTE0(_temp))self.cs(data_to_send)# 电机pwm数据 0-1000def ANO_DT_Send_MotoPWM(self, m_1, m_2, m_3, m_4, m_5, m_6, m_7, m_8):_cnt = 0data_to_send = []data_to_send.append(0xAA)data_to_send.append(0xAA)data_to_send.append(0x06)data_to_send.append(0)data_to_send.append(self.BYTE1(m_1))data_to_send.append(self.BYTE0(m_1))data_to_send.append(self.BYTE1(m_2))data_to_send.append(self.BYTE0(m_2))data_to_send.append(self.BYTE1(m_3))data_to_send.append(self.BYTE0(m_3))data_to_send.append(self.BYTE1(m_4))data_to_send.append(self.BYTE0(m_4))data_to_send.append(self.BYTE1(m_5))data_to_send.append(self.BYTE0(m_5))data_to_send.append(self.BYTE1(m_6))data_to_send.append(self.BYTE0(m_6))data_to_send.append(self.BYTE1(m_7))data_to_send.append(self.BYTE0(m_7))data_to_send.append(self.BYTE1(m_8))data_to_send.append(self.BYTE0(m_8))self.cs(data_to_send)

匿名上位机若干协议移植,2.4G控制

下面是个相似的项目:

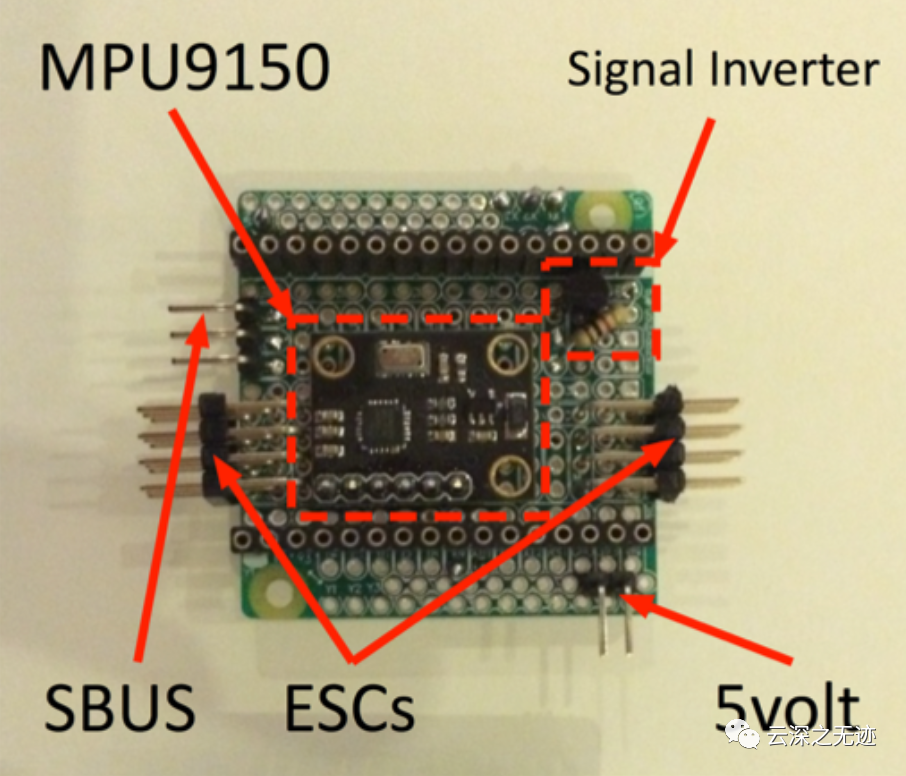

惯性测量单元 (IMU)

SBUS接口(用于连接SBUS RC接收器)

就是这么简单的东西。。。

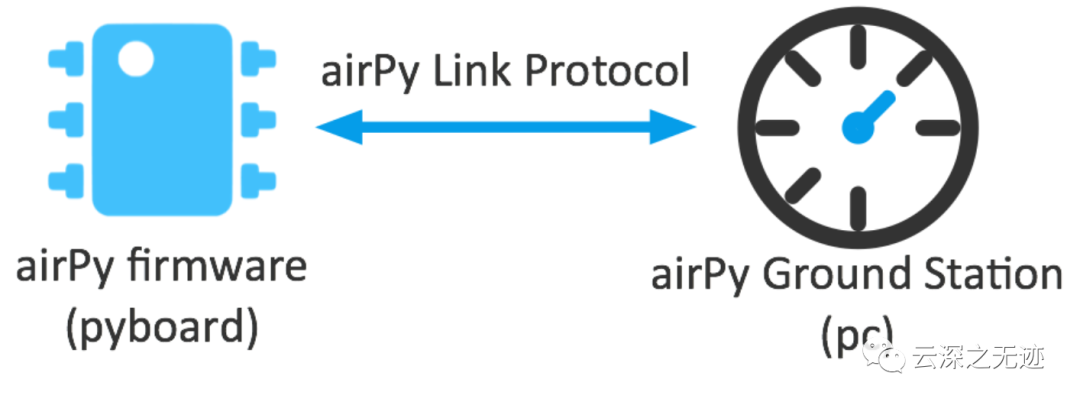

airPy代码分为3个模块:

airPy 固件:运行在 pyboard 上的 python 代码

airPy 地面站:在 PC 上运行的 JavaFx 代码,用于配置/调整 airPy 板

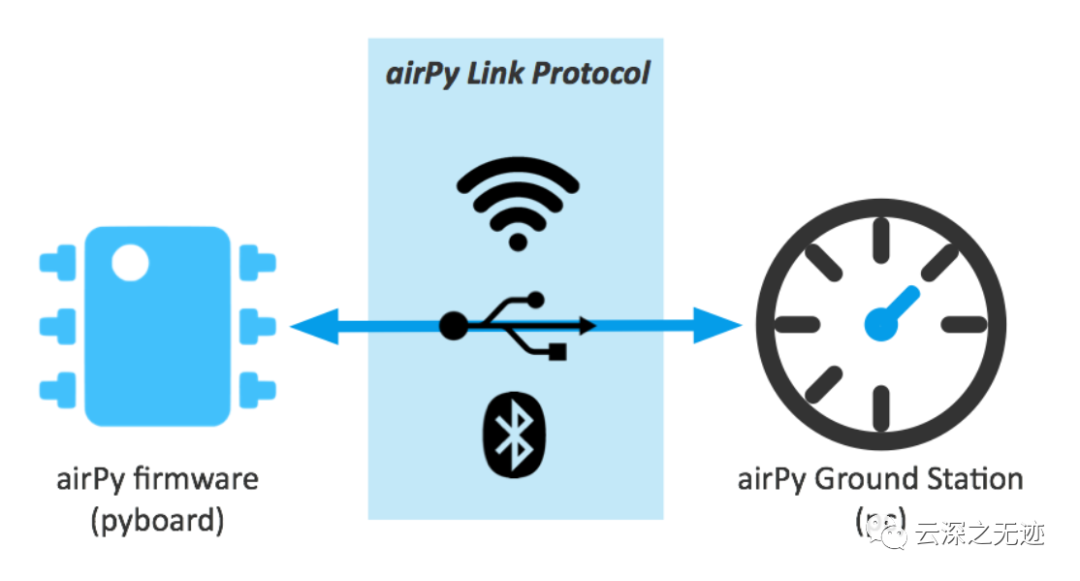

airPy Link Protocol:用于板卡与地面站通信的串行协议

airPy Link Protocol目前仅用于配置和调整目的。

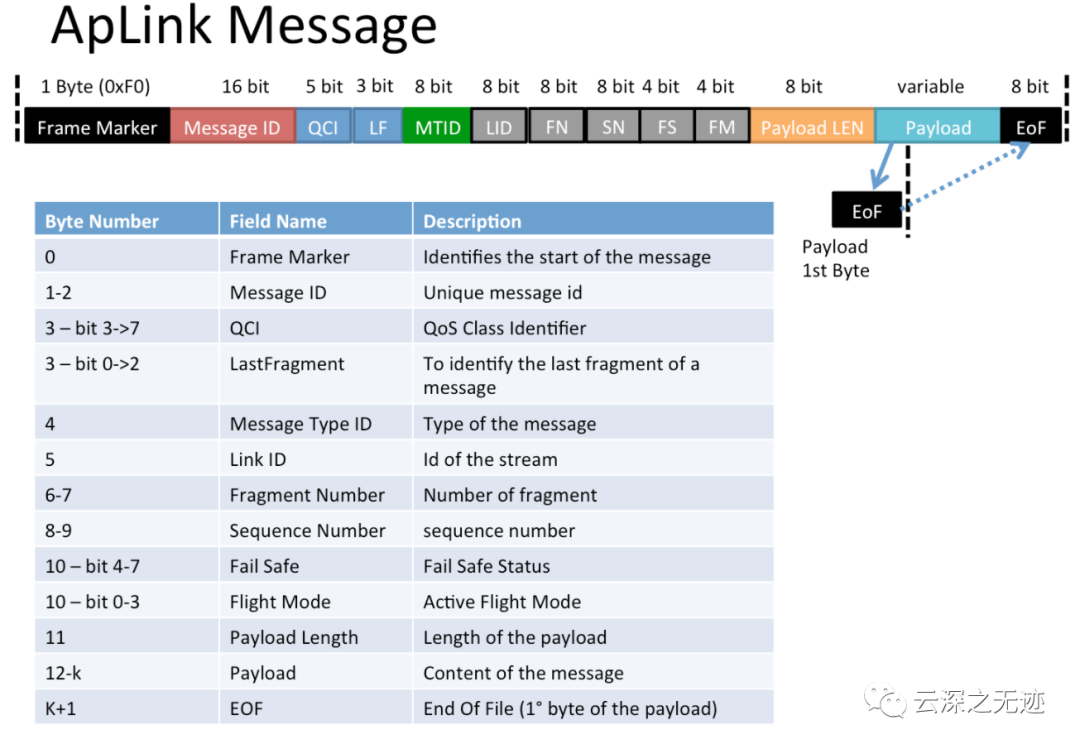

它是一种可变大小的串行协议,用于 pyboard 和地面站之间的数据通信。

这个想法是不仅在 USB 上而且在 Wi-fi、蓝牙和 ad hoc RF 通道(例如 433MHz)上使用这个协议。

每个 APLINK 消息都包含一个标头和一个可变大小的有效负载(取决于内容),如以下架构中所指定。

参考文章:

https://github.com/micropython-IMU/micropython-mpu9x50microPython-MPU9x50驱动

https://www.jianshu.com/u/38cc558a2c62micropython驱动的移植者

https://blog.csdn.net/qq_38721302/article/details/83095545STM32 驱动MPU6050(使用了本文的寄存器定义)

https://github.com/Sokrates80/air-py特别的,有一个microPython的飞控开源项目了,减少了我的工作量。

https://github.com/Sokrates80/airPy-GS相应搭配的地面站

https://github.com/micropython-IMU/micropython-fusionMicroPython 的单个平台上获取传感器数据并执行融合的情况

https://github.com/wagnerc4/flight_controller另外一个完整的项目

https://github.com/ArduPilot/ardupilotpid参考了这里,APM飞控

http://www.air-py.com/相关网站

开源的mpy飞控系统