恩智浦“FRDM-MCXN947”评测活动由安富利和与非网协同举办。本篇内容由与非网用户发布,已获转载许可。原文可在与非网(eefocus)工程师社区查看。

一个L9110S驱动可以控制一个电机,下图中的GroundStudio L9110s模块板载两个L9110s芯片,可以驱动两个直流电机。

此模块有6根引脚,如下:

简单来说L9110S的输入输出有以下四种情形:

从上图可知,只需要给IN1和IN2管脚输入不同的电平就能实现正转、反转,输入相同的电平就能停转。

需要注意,不要直接由开发板来给模块供电,因为L9110S模块可能因为需求的驱动功率太高而导致板子上的供电不平衡。

从上表可知,使用GPIO给IN1和IN2也能驱动电机,但是不能控制速度。现在我们需要实现能控制速度的电机驱动。自然而然想到了PWM调速。

假设给IN2管脚用GPIO控制,拉低电平,只需要PWM往IN1灌高电平就可以驱动电机正转,调节PWM占空比就可以实现电机转速;把IN2管脚拉高电平,用PMW往IN1灌低电平就可以实现电机反转,注意此时的占空比和转速是反着的,即占空比越大,转速越慢。

这里选择eFlexPWM产生PWM1_A通道的PWM波来控制电机,另外一个管脚用GPIO来控制电平调节正反转。

为了方便调试,先实现命令行接口,可以方便的通过串口输入命令调节参数控制电机正反转和转速。然后实现对应的电机驱动接口。

FreeRTOS-CLI新增命令行,支持如下的3种命令:

(滑动查看)

motor stop // 电机停转motor left speed // 电机正转,speed 表示速度,取值范围 [0, 100]motor right speed // 电机反转,speed 表示范围,取值范围 [0, 100]

当前命令行的解析函数prvMotorCommand()如下,其实最终调用的函数是分别是motor_stop(),motor_left(speed)和motor_right(speed)这三个函数。

(滑动查看)

/*** @brief 直流电机命令的实现** motor left/right speed 其中 speed 取值范围是 [0, 100]* motor stop** 示例:* motor left 0* motor left 100* motor right 20* motor right 80* motor stop 停转** @param pcWriteBuffer* @param xWriteBufferLen* @param pcCommandString* @return BaseType_t*/static BaseType_t prvMotorCommand( char *pcWriteBuffer, size_t xWriteBufferLen, const char *pcCommandString ){configASSERT(pcWriteBuffer);br/* param1: left/right/stop */const char *paramMotorCmd1 = NULL;BaseType_t paramMotorCmd1Length = 0;br/* param2: speed */const char *paramMotorCmd2 = NULL;BaseType_t paramMotorCmd2Length = 0;uint32_t speed = 0;br// 首先清除输出缓冲区旧的内容memset(pcWriteBuffer, 0, xWriteBufferLen);br/* arg0 arg1 arg2 *//* 命令形式1:motor left/right speed *//* 命令形式2:motor stop */paramMotorCmd1 = FreeRTOS_CLIGetParameter(pcCommandString, 1, ¶mMotorCmd1Length);brif (strncmp("stop", paramMotorCmd1, strlen("stop")) == 0) {motor_stop();sprintf(pcWriteBuffer, "\r\n motor_stop() \r\n");} else {/* 获取 speed */paramMotorCmd2 = FreeRTOS_CLIGetParameter(pcCommandString, 2, ¶mMotorCmd2Length);if (paramMotorCmd2 != NULL) {speed = strtoul(paramMotorCmd2, NULL, 10);brif (speed >= 100) {speed = 99; /* NOTE: PWM 占空比 <= 100 但由于两个高电平导致电机停转,所以占空比应该 < 100 */}}brif (strncmp("left", paramMotorCmd1, strlen("left")) == 0) {sprintf(pcWriteBuffer, "\r\n motor_left(%u) \r\n", speed);motor_left(speed);} else if (strncmp("right", paramMotorCmd1, strlen("right")) == 0) {sprintf(pcWriteBuffer, "\r\n motor_right(%u) \r\n", speed);motor_right(speed);} else {sprintf(pcWriteBuffer, "\r\nError: arg1 should be left/right\r\n");}}br/* There is no more data to return after this single string, so return pdFALSE. */return pdFALSE;}

PWM和GPIO初始化

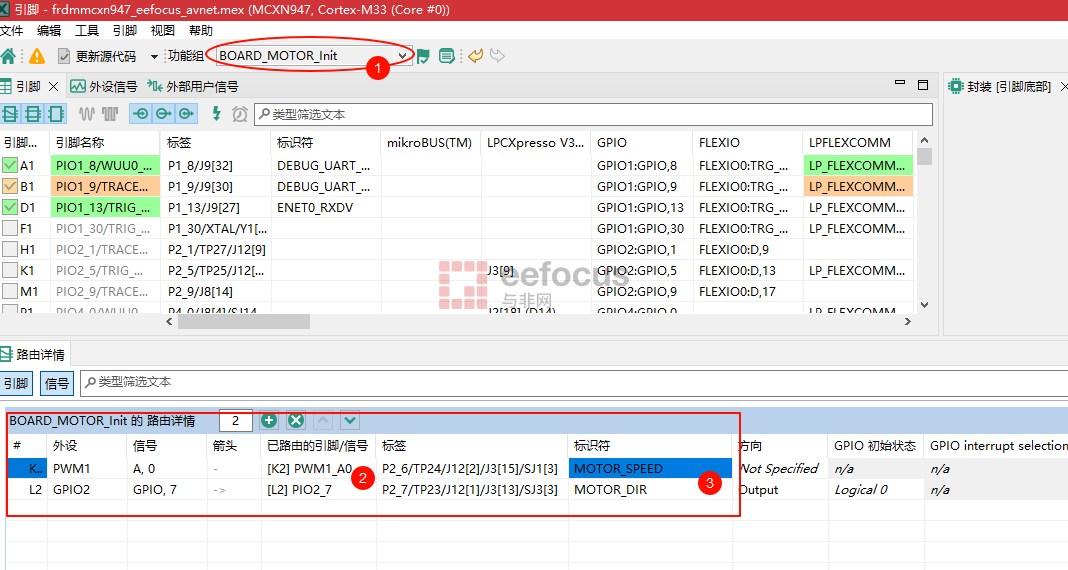

通过MCUXpresso Config Tools来实现,配置J3.15为PWM1_A0,配置J3.13为GPIO输出模式。生成代码,自动保存在pin_mux.c文件中。

在MCUXpresso Config Tools中,点击(1)处新建分组BOARD_MOTOR_Init,把电机相关的管脚都放在同一个组里初始化;

在(2)处可以看到J3.15配置为PWM1_A0信号,J3.13配置为PIO2_7且为输出;

在(3)处给管脚添加标识符,会生成相对应的宏定义。

对应的管脚初始化代码如下:

(滑动查看)

void BOARD_MOTOR_Init(void){/* Enables the clock for GPIO2: Enables clock */CLOCK_EnableClock(kCLOCK_Gpio2);/* Enables the clock for PORT2: Enables clock */CLOCK_EnableClock(kCLOCK_Port2);gpio_pin_config_t MOTOR_DIR_config = {.pinDirection = kGPIO_DigitalOutput,.outputLogic = 0U};/* Initialize GPIO functionality on pin PIO2_7 (pin L2) */GPIO_PinInit(MOTOR_MOTOR_DIR_GPIO, MOTOR_MOTOR_DIR_PIN, &MOTOR_DIR_config);/* PORT2_6 (pin K2) is configured as PWM1_A0 */PORT_SetPinMux(MOTOR_MOTOR_SPEED_PORT, MOTOR_MOTOR_SPEED_PIN, kPORT_MuxAlt5);PORT2->PCR[6] = ((PORT2->PCR[6] &/* Mask bits to zero which are setting */(~(PORT_PCR_IBE_MASK)))/* Input Buffer Enable: Enables. */| PORT_PCR_IBE(PCR_IBE_ibe1));/* PORT2_7 (pin L2) is configured as PIO2_7 */PORT_SetPinMux(MOTOR_MOTOR_DIR_PORT, MOTOR_MOTOR_DIR_PIN, kPORT_MuxAlt0);PORT2->PCR[7] = ((PORT2->PCR[7] &/* Mask bits to zero which are setting */(~(PORT_PCR_IBE_MASK)))/* Input Buffer Enable: Enables. */| PORT_PCR_IBE(PCR_IBE_ibe1));}

电机控制

需要实现4个函数,分别是:

motor_init()

motor_stop()

motor_left()

motor_right()

公共的类型和变量

(滑动查看)

br/******************************************************************************** Definitions******************************************************************************//* The PWM base address *//* Definition for default PWM frequence in hz. */br/* Macros ----------------------------------------------------------------------------------------*/brbr/* Data Types ------------------------------------------------------------------------------------*/brtypedef enum {MOTOR_DIR_LEFT = 0,MOTOR_DIR_RIGHT = 1,} motor_dir_e;brstatic uint32_t pwmSourceClockInHz;static uint32_t pwmFrequencyInHz;static pwm_signal_param_t pwmSignal = { 0 };static motor_dir_e m_motor_dir = MOTOR_DIR_LEFT;

motor_init()

(滑动查看)

static void PWM_DRV_Init2PhPwm(void){uint16_t deadTimeVal;br/* Set deadtime count, we set this to about 650ns */deadTimeVal = ((uint64_t)pwmSourceClockInHz * 650) / 1000000000;brpwmSignal.pwmChannel = kPWM_PwmA;pwmSignal.level = kPWM_HighTrue;pwmSignal.dutyCyclePercent = 30; /* x percent dutycycle */pwmSignal.deadtimeValue = deadTimeVal;pwmSignal.faultState = kPWM_PwmFaultState0;pwmSignal.pwmchannelenable = true;br/*********** PWMA_SM0 - phase A, configuration, setup 2 channel as an example ************/PWM_SetupPwm(BOARD_PWM_BASEADDR, kPWM_Module_0, &pwmSignal, 1,kPWM_SignedCenterAligned, pwmFrequencyInHz, pwmSourceClockInHz);}br/*** @brief 直流电机初始化,即 PWM1 的通道A和通道B初始化** @return int 0 on success, others on failure.*/int motor_init(void){pwm_config_t pwmConfig;pwm_fault_param_t faultConfig;brpwmSourceClockInHz = PWM_SRC_CLK_FREQ;pwmFrequencyInHz = APP_DEFAULT_PWM_FREQUENCY;brSYSCON->PWM1SUBCTL |= SYSCON_PWM1SUBCTL_CLK0_EN_MASK; /* 只使能子模块0 */brPWM_GetDefaultConfig(&pwmConfig);brpwmConfig.reloadLogic = kPWM_ReloadPwmFullCycle; /* use full cycle reload */pwmConfig.pairOperation = kPWM_Independent; /* PWM A & PWM B operate as 2 independent channels */pwmConfig.enableDebugMode = true;brif (PWM_Init(BOARD_PWM_BASEADDR, kPWM_Module_0, &pwmConfig) == kStatus_Fail){PRINTF("PWM initialization failed\r\n");return 1;}brPWM_FaultDefaultConfig(&faultConfig);brfaultConfig.faultLevel = DEMO_PWM_FAULT_LEVEL;br/* Sets up the PWM fault protection */PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_0, &faultConfig);PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_1, &faultConfig);PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_2, &faultConfig);PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_3, &faultConfig);br/* Set PWM fault disable mapping for submodule 0 */PWM_SetupFaultDisableMap(BOARD_PWM_BASEADDR, kPWM_Module_0, kPWM_PwmA, kPWM_faultchannel_0,kPWM_FaultDisable_0 | kPWM_FaultDisable_1 | kPWM_FaultDisable_2 | kPWM_FaultDisable_3);br/* Call the init function with demo configuration */PWM_DRV_Init2PhPwm();br/* Set the load okay bit for all submodules to load registers from their buffer */PWM_SetPwmLdok(BOARD_PWM_BASEADDR, kPWM_Control_Module_0, true);brPWM_StartTimer(BOARD_PWM_BASEADDR, kPWM_Control_Module_0);brmotor_stop();brreturn 0;}

motor_stop()

(滑动查看)

void motor_stop(void){if (m_motor_dir == MOTOR_DIR_LEFT) {MOTOR_DIR_SET_LEFT();PWM_UpdatePwmDutycycle(BOARD_PWM_BASEADDR, kPWM_Module_0, kPWM_PwmA, kPWM_SignedCenterAligned, 0);/* Set the load okay bit for all submodules to load registers from their buffer */PWM_SetPwmLdok(BOARD_PWM_BASEADDR, kPWM_Control_Module_0, true);} else {MOTOR_DIR_SET_RIGHT();PWM_UpdatePwmDutycycle(BOARD_PWM_BASEADDR, kPWM_Module_0, kPWM_PwmA, kPWM_SignedCenterAligned, 100);/* Set the load okay bit for all submodules to load registers from their buffer */PWM_SetPwmLdok(BOARD_PWM_BASEADDR, kPWM_Control_Module_0, true);}}

motor_left(speed)

(滑动查看)

/*** @brief 正转* @param speed 占空比,[0~100]*/void motor_left(uint32_t speed){MOTOR_DIR_SET_LEFT();m_motor_dir = MOTOR_DIR_LEFT;brPWM_UpdatePwmDutycycle(BOARD_PWM_BASEADDR, kPWM_Module_0, kPWM_PwmA, kPWM_SignedCenterAligned, speed);/* Set the load okay bit for all submodules to load registers from their buffer */PWM_SetPwmLdok(BOARD_PWM_BASEADDR, kPWM_Control_Module_0, true);PWM_StartTimer(BOARD_PWM_BASEADDR, kPWM_Control_Module_0);}

motor_right(speed)

(滑动查看)

/*** @brief 反转* @param speed*/void motor_right(uint32_t speed){MOTOR_DIR_SET_RIGHT();m_motor_dir = MOTOR_DIR_RIGHT;speed = 100 - speed;brPWM_UpdatePwmDutycycle(BOARD_PWM_BASEADDR, kPWM_Module_0, kPWM_PwmA, kPWM_SignedCenterAligned, speed);// PWM_SetChannelOutput(BOARD_PWM_BASEADDR, kPWM_Module_0, kPWM_PwmA, kPWM_InvertState);/* Set the load okay bit for all submodules to load registers from their buffer */PWM_SetPwmLdok(BOARD_PWM_BASEADDR, kPWM_Control_Module_0, true);brPWM_StartTimer(BOARD_PWM_BASEADDR, kPWM_Control_Module_0);}

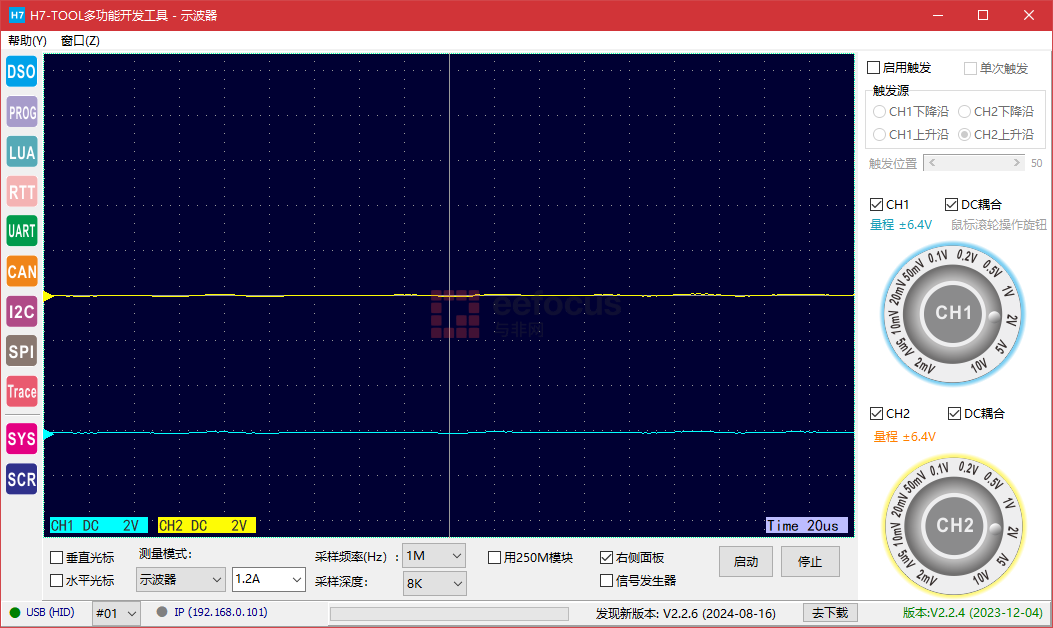

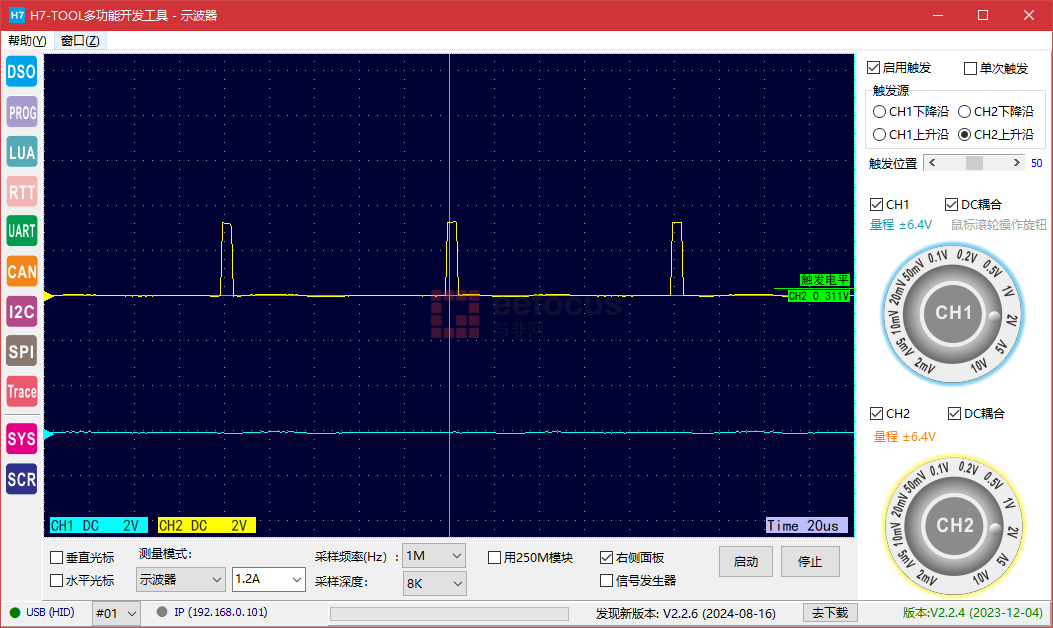

上面黄色的是CH2,即PWM1_A信号(J3.15);

下面绿色的是CH1,即GPIO信号(J3.13);

电机正转motor left时CH1输出低电平;

电机反转motor right时CH1输出高电平。

motor stop

两路信号都是低电平。电机停转。

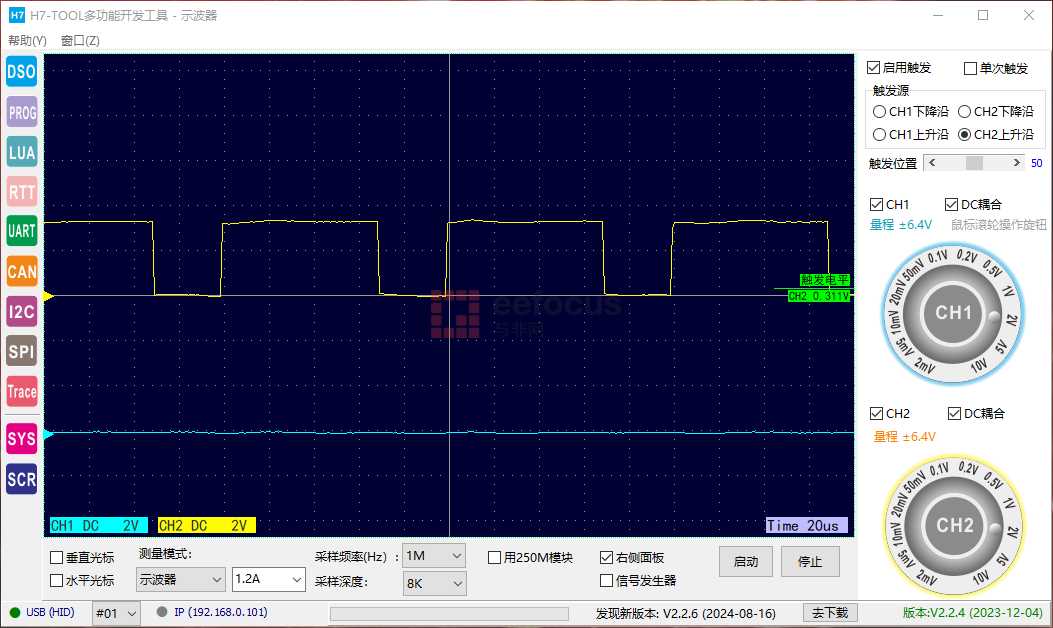

motor left 5

电机正转,速度为5。示波器观测PWM1_A占空比为5。

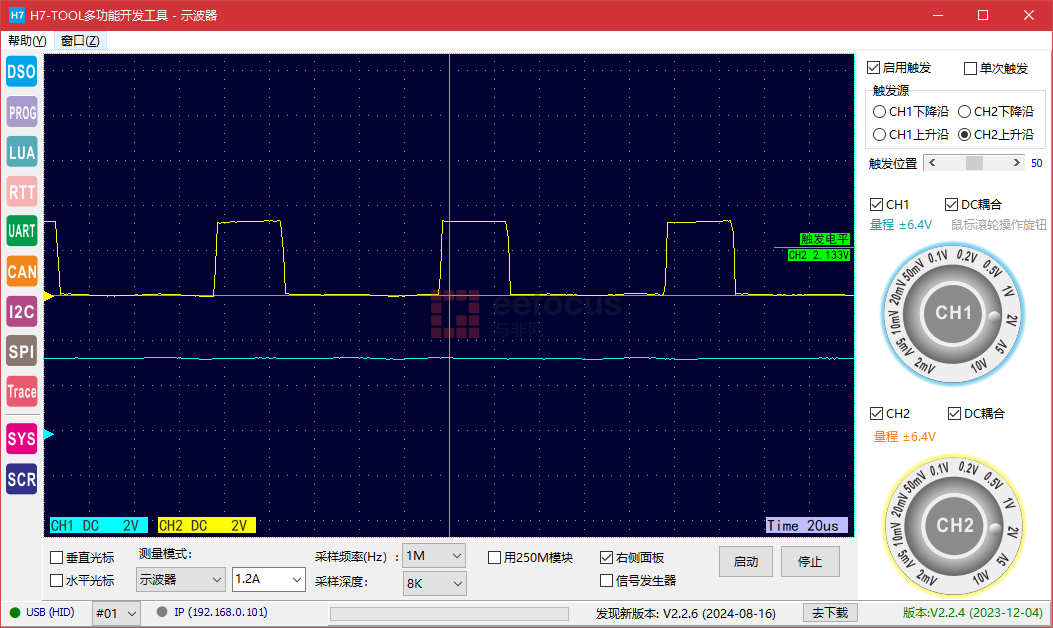

motor left 70

电机正转,速度为70。示波器观测PWM1_A占空比为70。

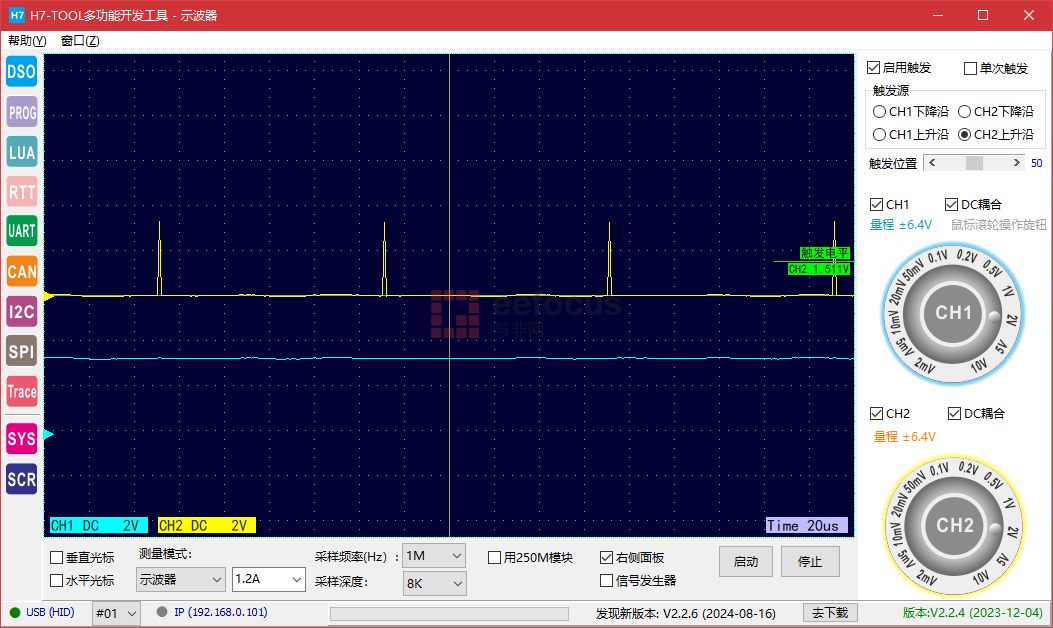

motor left 100

虽然PWM占空比可以设置成100%,但是两个高电平导致电机停转,所以这里把占空比合理的范围是[0,99]。

motor right 5

motor right 70

motor right 100

—— 更多精彩内容 ——

关于安富利

安富利是全球领先的技术分销商和解决方案提供商,在过去一个多世纪里一直秉持初心,致力于满足客户不断变化的需求。通过遍布全球的专业化和区域化业务覆盖,安富利可在产品生命周期的每个阶段为客户和供应商提供支持。安富利能够帮助各种类型的公司适应不断变化的市场环境,在产品开发过程中加快设计和供应速度。安富利在整个技术价值链中处于中心位置,这种独特的地位和视角让其成为了值得信赖的合作伙伴,能够帮助客户解决复杂的设计和供应链难题,从而更快地实现营收。了解有关安富利的更多信息,请访问www.avnet.com