目录:

上篇文章(如上链接)介绍了如何基于S32K144驱动NSD8381,当时因为篇幅原因,没有介绍NSD8381的堵转检测功能。本文借助freemaster,让读者更方便地理解NSD8381的堵转检测功能。

纳芯微官网的步进电机驱动NSD8381调试指南[1]有介绍NSD8381的堵转检测功能,相关内容摘录如下:

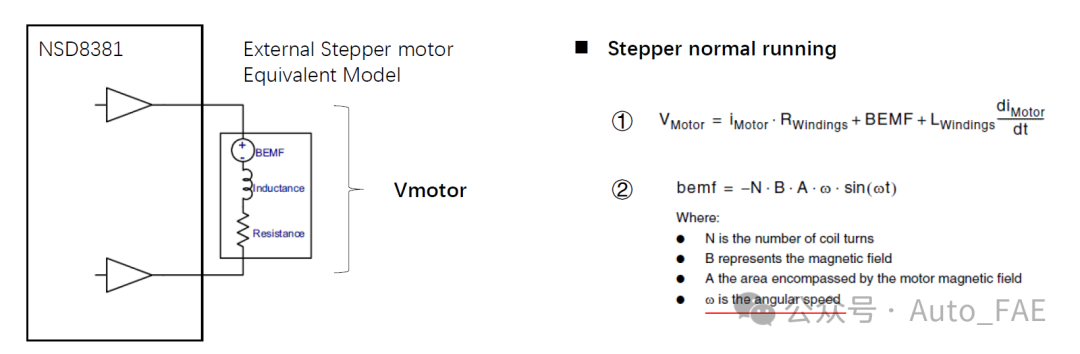

上图左边是步进电机绕组的等效模型。当电机正常转动的时候,根据上图右边的公式①可以得到电机绕组两侧的电压Vmotor。根据公式②可得到电机的反电势BEMF,其中N为线圈的绕组数量,B代表磁场强度,A是被电机磁场所包围的面积,w是电机转动的角速度。

由公式①可知,当流过电机的电流为零时,电机绕组两侧的电压是BEMF,即反电势电压。由公式②可知,反电势电压和电机的角速度成正比,当电机堵转的时候,速度接近于零,此时反电势也接近于零。因此,可以利用检测绕组电流为零时的绕组电压来检测反电势。

补充说明:

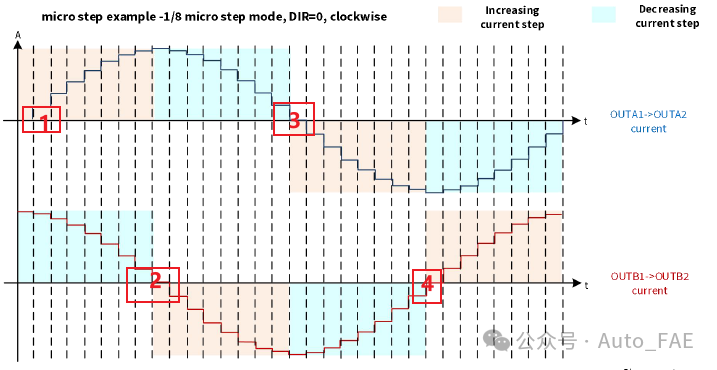

如下图所示,以1/8微步为例,在一个正弦波周期内,A、B线圈分别有两次过零step。

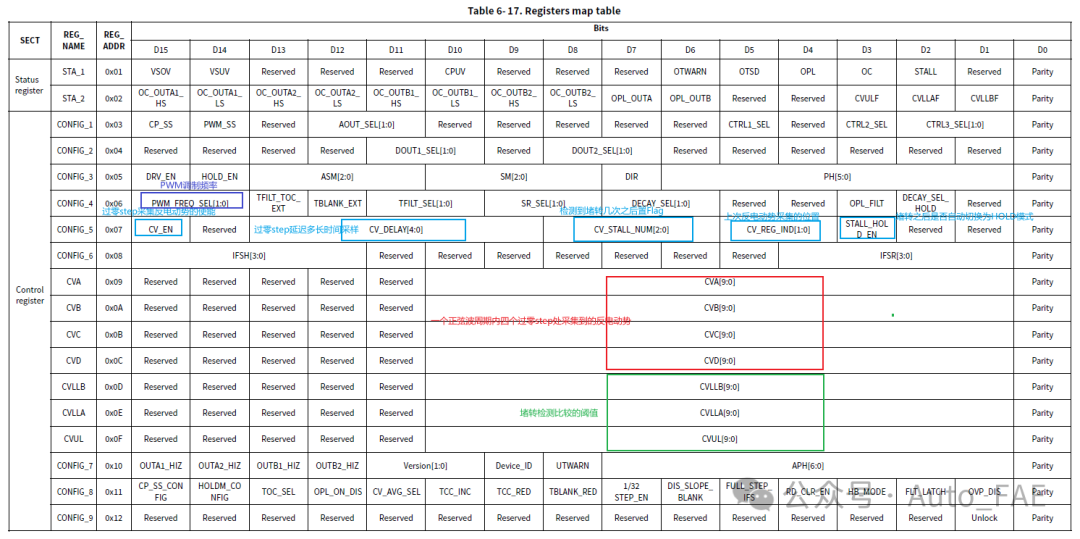

上图标注都是和堵转检测相关的寄存器,说明如下:

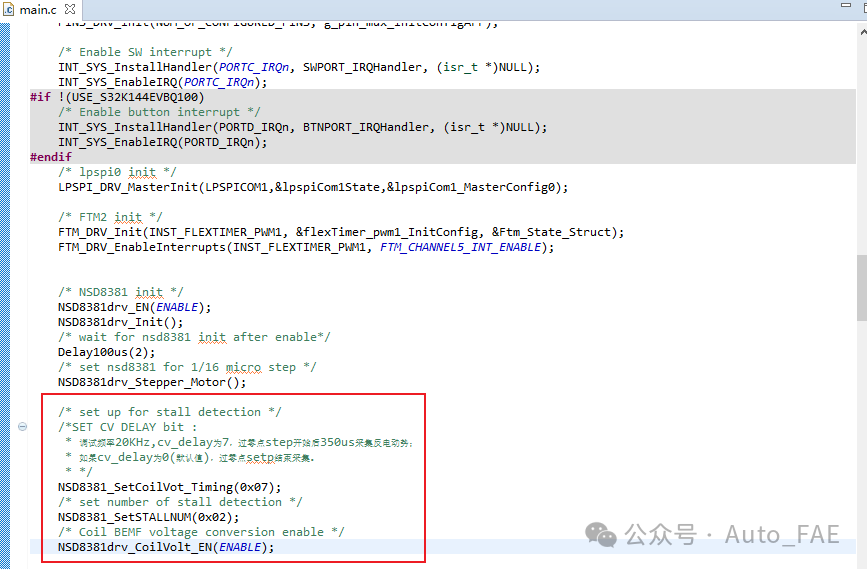

PWM_FREQ_SEL[1:0] 使用默认值0x00,即使用20K的PWM调制频率,周期为50us;CV_DELAY[4:0]配置为7,那么NSD8381在过零step之后350us处采集反电动势。

以读取CVA[9:0]为例,计算公式为

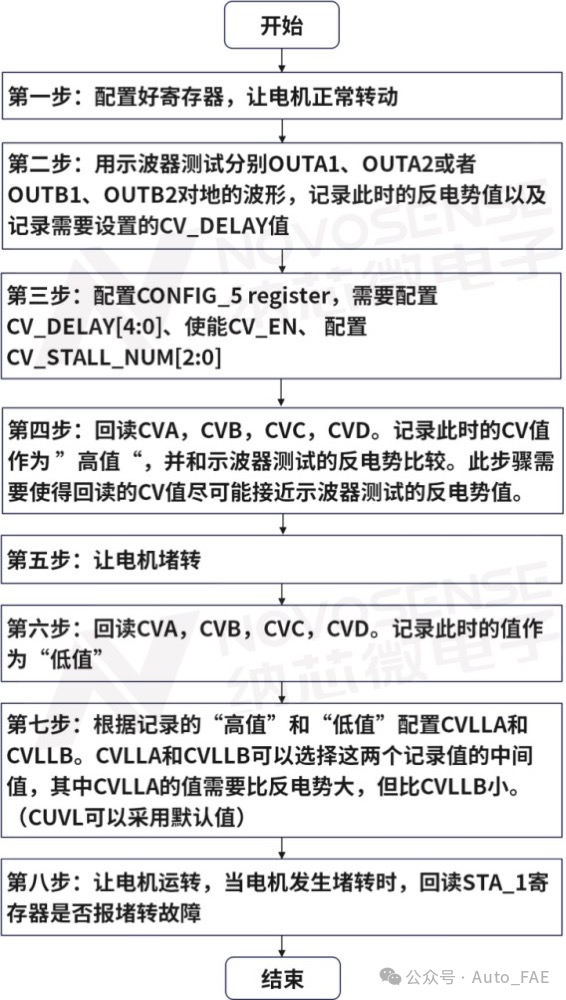

摘录纳芯微官网介绍的堵转配置流程图如下:

下面基于这套流程图进行介绍。

Phase_Count = NSD8381drv_GetPH();

if(Phase_Count == 0)

{

Coil_Volt_A = NSD8381drv_ReadcoilBEMF(MCVA);

printf("voltage of coil A is %d\r\n", Coil_Volt_A);

Coil_Volt_B = NSD8381drv_ReadcoilBEMF(MCVB);

printf("voltage of coil B is %d\r\n", Coil_Volt_B);

Coil_Volt_C = NSD8381drv_ReadcoilBEMF(MCVC);

printf("voltage of coil C is %d\r\n", Coil_Volt_C);

Coil_Volt_D = NSD8381drv_ReadcoilBEMF(MCVD);

printf("voltage of coil D is %d\r\n", Coil_Volt_D);

/* Last coil BEMF voltage conversion store register

* 00:CVA

* 01:CVB

* 10:CVC

* 11:CVD

* */

if(NSD8381_ReadCVLUR() == 0x00)

{

Latest_Coil_Volt = Coil_Volt_A;

printf("Latest voltage of coil is CVA:%d\r\n", Latest_Coil_Volt);

Float_Coil_volt = ((float)Latest_Coil_Volt/1023)*28;

printf("latest real voltage of coil is:%f V\r\n", Float_Coil_volt);

}

}

elseif(Phase_Count == 16)

{

Coil_Volt_A = NSD8381drv_ReadcoilBEMF(MCVA);

printf("voltage of coil A is %d\r\n", Coil_Volt_A);

Coil_Volt_B = NSD8381drv_ReadcoilBEMF(MCVB);

printf("voltage of coil B is %d\r\n", Coil_Volt_B);

Coil_Volt_C = NSD8381drv_ReadcoilBEMF(MCVC);

printf("voltage of coil C is %d\r\n", Coil_Volt_C);

Coil_Volt_D = NSD8381drv_ReadcoilBEMF(MCVD);

printf("voltage of coil D is %d\r\n", Coil_Volt_D);

/* Last coil BEMF voltage conversion store register

* 00:CVA

* 01:CVB

* 10:CVC

* 11:CVD

* */

if(NSD8381_ReadCVLUR() == 0x01)

{

Latest_Coil_Volt = Coil_Volt_B;

printf("Latest voltage of coil is CVB:%d\r\n", Latest_Coil_Volt);

Float_Coil_volt = ((float)Latest_Coil_Volt/1023)*28;

printf("latest real voltage of coil is:%f V\r\n", Float_Coil_volt);

}

}

elseif(Phase_Count == 32)

{

Coil_Volt_A = NSD8381drv_ReadcoilBEMF(MCVA);

printf("voltage of coil A is %d\r\n", Coil_Volt_A);

Coil_Volt_B = NSD8381drv_ReadcoilBEMF(MCVB);

printf("voltage of coil B is %d\r\n", Coil_Volt_B);

Coil_Volt_C = NSD8381drv_ReadcoilBEMF(MCVC);

printf("voltage of coil C is %d\r\n", Coil_Volt_C);

Coil_Volt_D = NSD8381drv_ReadcoilBEMF(MCVD);

printf("voltage of coil D is %d\r\n", Coil_Volt_D);

/* Last coil BEMF voltage conversion store register

* 00:CVA

* 01:CVB

* 10:CVC

* 11:CVD

* */

if(NSD8381_ReadCVLUR() == 0x02)

{

Latest_Coil_Volt = Coil_Volt_C;

printf("Latest voltage of coil is CVC:%d\r\n", Latest_Coil_Volt);

Float_Coil_volt = ((float)Latest_Coil_Volt/1023)*28;

printf("latest real voltage of coil is:%f V\r\n", Float_Coil_volt);

}

}

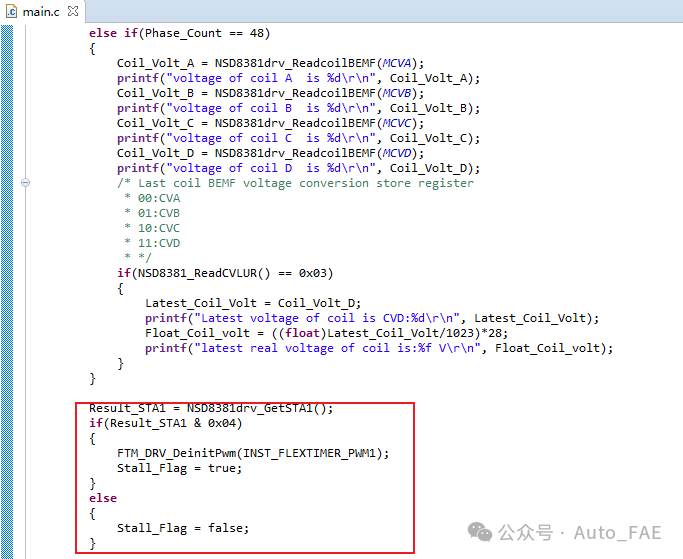

elseif(Phase_Count == 48)

{

Coil_Volt_A = NSD8381drv_ReadcoilBEMF(MCVA);

printf("voltage of coil A is %d\r\n", Coil_Volt_A);

Coil_Volt_B = NSD8381drv_ReadcoilBEMF(MCVB);

printf("voltage of coil B is %d\r\n", Coil_Volt_B);

Coil_Volt_C = NSD8381drv_ReadcoilBEMF(MCVC);

printf("voltage of coil C is %d\r\n", Coil_Volt_C);

Coil_Volt_D = NSD8381drv_ReadcoilBEMF(MCVD);

printf("voltage of coil D is %d\r\n", Coil_Volt_D);

/* Last coil BEMF voltage conversion store register

* 00:CVA

* 01:CVB

* 10:CVC

* 11:CVD

* */

if(NSD8381_ReadCVLUR() == 0x03)

{

Latest_Coil_Volt = Coil_Volt_D;

printf("Latest voltage of coil is CVD:%d\r\n", Latest_Coil_Volt);

Float_Coil_volt = ((float)Latest_Coil_Volt/1023)*28;

printf("latest real voltage of coil is:%f V\r\n", Float_Coil_volt);

}

}

关于Freemaster的使用,可以参考如下文章:

FreeMASTER快速入门

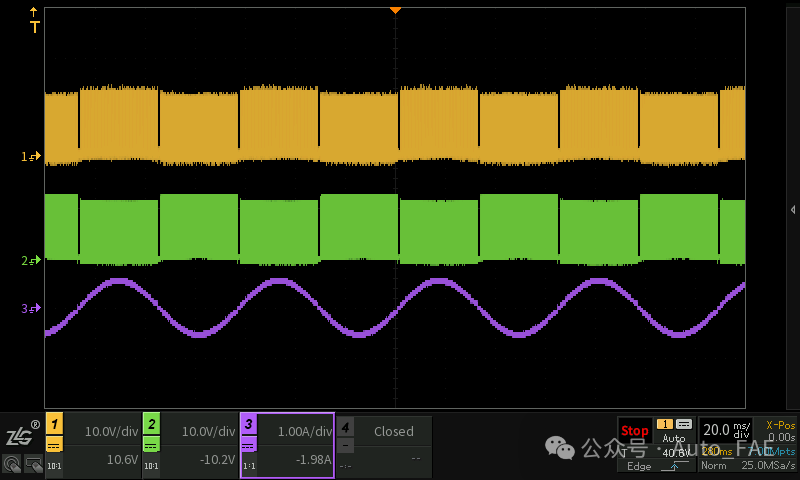

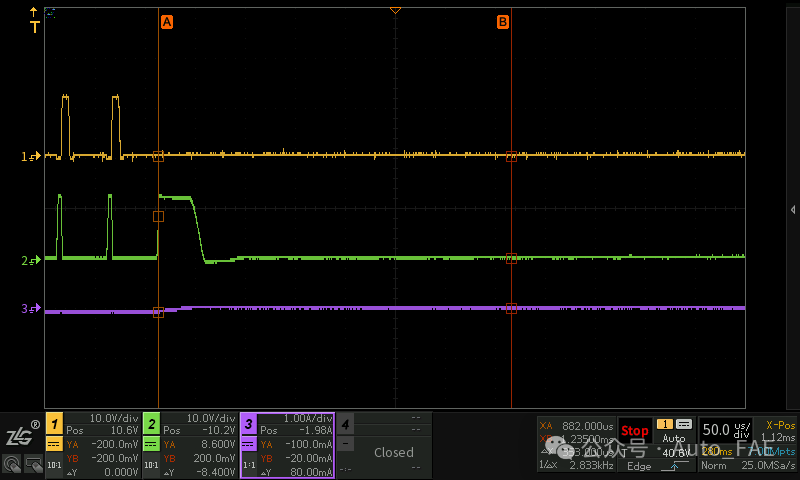

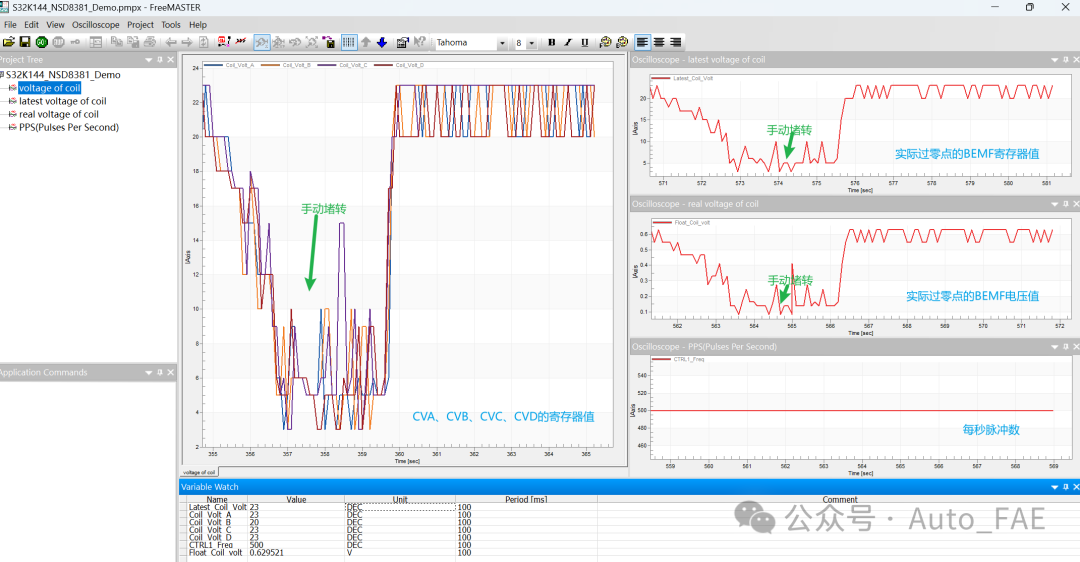

从上图中可以看出,正常运行时回读到的反电动势电压在0.55V到0.6V之间,和示波器抓取到的数值(0.2V)有些差异,这里使用芯片回读值。同时可以看到手动堵转时的反电动势仍有0.2V左右,主要是手指无法让电机完全停止转动。

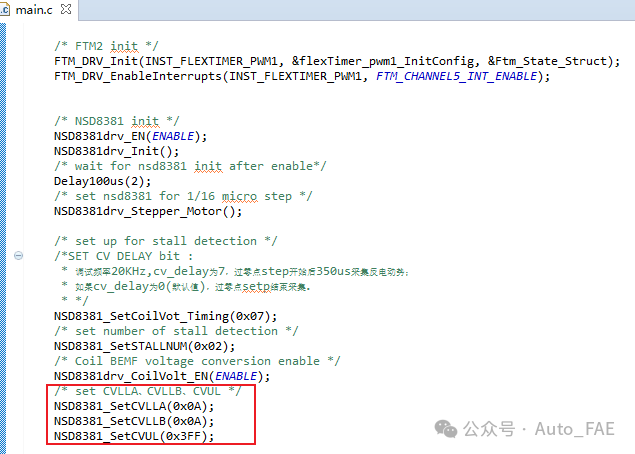

基于上图得到的数据,我们将CVLLA和CVLLB都设置为0x0A,对应的电压在0.27V左右,处于0.2V和0.5V之间。CVUL采用默认值0x3FF,对应电压28V。对应代码配置如下:

堵转后不关闭PWM波,对应的FreeMaster界面动图如下。可以看到手动堵转后,过零点的反电动势明细下降很多。

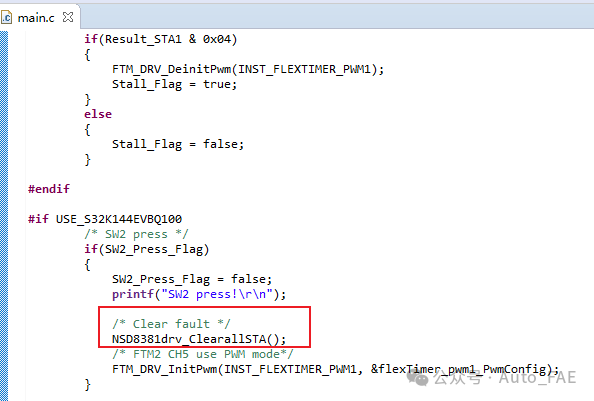

堵转后关闭PWM波,对应的FreeMaster界面动图如下。当手动堵转后,NSD8381的STA_1寄存器对应的STALL bit(下图底部的变量Stall_Flag)被置位,电机停止运行。

实际测试发现,NSD8381的供电电压、电机的温度、电机运行方向对获取的反电动势值都有影响。在实际项目应用时,需要结合产品的工作环境,模拟多种环境去测试电机正常运行时和堵转时的反电动势,设置合适的CVLLA、CVLLB、CVUL。

步进电机驱动NSD8381调试指南: https://www.novosns.com/technical-articles-385