最近JDI(日本显示器公司)发布消息称,其位于千叶县茂原的G6工厂,成功开发出全球首个背板革新技术,从根本上改善了目前传统氧化物半导体薄膜晶体管 (OS-TFT) 的性能,进一步将立即开始推进该技术的商业化。

1. 概要

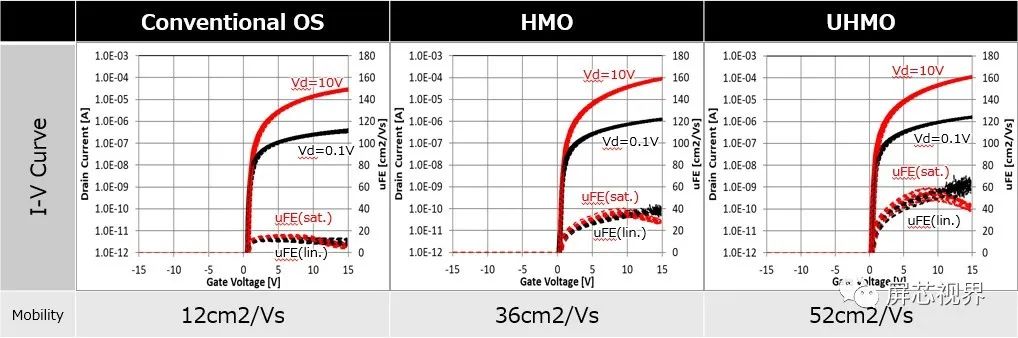

高迁移率氧化物半导体 (HMO,High Mobility Oxide)技术,可生成的场效应迁移率,是传统 OS-TFT 技术2 倍以上。

超高迁移率氧化物半导体 (UHMO,Ultra High Mobility Oxide)技术的迁移率是传统 OS-TFT 技术4 倍以上。

UHMO在JDI G6量产线上的场效应迁移率为52cm2/Vs,氧化物半导体TFT在量产生产线上实现了非常高速的特性。

可以说,该技术已经可实现与 LTPS 相接近水平的导通电流,同时保持低截止漏电流。

另一个优势是,虽然传统的高迁移率 AMOLED 背板需要 LTPS 技术,这将玻璃基板尺寸限制在 G6,但该技术可用于 G8 或更大的生产线。

据悉,JDI 称该技术将极大地加速显示技术创新,并有助于提高 OLED 和 LCD 显示性能,包括:

显示器的低功耗

提高VR/AR显示性能,更高分辨率和更高刷新率,为用户带来更深的沉浸感和现实融合

可提高透明显示器的更高透明度和图像质量,以及实现显示器的大尺寸化

传统的 OS-TFT 技术存在偏置温度应力 (BTS) 的问题,当试图获得高场效应迁移率时,这会导致可靠性差和图像劣化问题出现。

一直以来,高场效应和BST二者难以共存的问题成为需要解决的课题。

此次,JDI通过利用多年来在OS-TFT积累的制造工艺专有技术,克服困难,实现了具有卓越特性的全新OS-TFT突破性技术。该技术采用了日本出光兴产株式会社开发的结晶氧化物材料,同时实现了高场效应迁移率和稳定的BTS,同时实现了OS-TFT的低截止漏电流和LTPS的图像驱动稳定性。

2. 未来展望

(1) 关于量产计划:

已经和客户进行了关于该技术量产日期的商谈,目前计划从2024年开始量产。

(2) 关于销售目标:

JDI预计该突破性技术,今后在显示类型和客户应用中具有极其广泛的应用。

计划将该技术与下一代 OLED 技术相结合,以扩大G6可穿戴设备生产,2025财年约 250 亿日元(约人民币13亿元),2026财年为 500 亿日元(约人民币26亿元)。

(3) 关于技术开发成本:

由于该技术建立在JDI多年积累的背板技术核心研发技术之上。

因此,商业化所需的额外费用将低于10亿日元。

(4) 对业绩影响:

预测对2022年3月期业绩影响不大,但将加强 JDI 的全球显示技术领导地位,并推动 JDI 的长期可持续增长,为中长期企业价值提升做出贡献。

筹建技术交流群

全网召集

TFT器件发烧友

加好友请注明研究T龄

附档原文说明:

[Provisional Translation Only]

This English translation of the original Japanese document is provided solely for information purposes. Should there be any discrepancies between this translation and the Japanese original, the latter shall prevail.

March 30, 2022

Japan Display Inc. (Tokyo Stock Exchange First Section, 6740) Representative: Scott Callon, Chairman & CEO

Inquiries: Akihito Okochi, CFO Telephone: +81-3-6732-8100 www.j-display.com/english

JDI Develops World’s First G6 Oxide Semiconductor TFT with 4X Improvement in Field-Effect Mobility

-Breakthrough in Display Performance-

Japan Display Inc. (JDI) has successfully developed the world’s first backplane technology to radically improve the properties of conventional oxide semiconductor thin film transistors (OS-TFT) at its G6 Plant in Mobara, Japan, and will begin immediate commercialization of this new technology.

Details of JDI’s New Technology

JDI’s new OS-TFT technology generates high-mobility oxide semiconductors (HMO), which have 2X the field-effect mobility of conventional OS-TFTs, and ultra-high mobility oxide semiconductors (UHMO), which have 4X higher field-effect mobility than conventional OS-TFT (hereafter, HMO/UHMO collectively referred to as “HMO”).

UHMO’s field-effect mobility on JDI’s G6 mass production line is 52cm2/Vs, an extraordinarily high level. More broadly, HMO enables the same level of on-current flow as LTPS, while maintaining low off-leak current.

A further advantage of HMO is that while conventional high-mobility AMOLED backplanes require LTPS technology, which limits glass substrate sizes to G6, HMO can be used in G8 or larger production lines.

Conventional OS | HMO | UHMO | |

Field-Effect Mobility | 12cm2/Vs | 36cm2/Vs | 52cm2/Vs |

Transistor I-V Characteristic Comparison

JDI believes HMO will drastically accelerate display technology innovation and contribute to significant improvements in both OLED and LCD display performance, including:

Lower power consumption;

For Metaverse VR/AR displays, higher resolutions and higher refresh rates, driving deeper immersion and reality integration for users in the Metaverse;

For transparent displays, higher transparency and image quality and bigger displays.

Lower Power Consumption Higher Resolution

HMO Attributes

Conventional OS-TFTs have a problem of bias temperature stress (BTS), which causes poor reliability and image deterioration when trying to obtain high field-effect mobility.

However, by leveraging the manufacturing process know-how JDI has developed over many years, JDI has overcome these challenges with HMO, which is a new, breakthrough OS-TFT with superior characteristics.

HMO achieves both high field-effect mobility and stable BTS to concurrently realize OS-TFT’s low off-leak current and LTPS’s image driving stability.HMO uses crystalline oxide materials developed by Idemitsu Kosan Co., Ltd.

Field-Effect Mobility Comparison

Bias Temperature Stress Variability Characteristic Comparison

PBTS:Positive Bias Temperature Stress NBTIS:Negative Bias Temperature Irradiation Stress

Forward Outlook

HMO Mass Production Start

JDI is already in HMO deployment discussions with multiple customers and plans to start mass production in 2024.

HMO Sales Target

JDI believes that HMO is a breakthrough technology that has extremely broad application across display types and customer applications. As one use case, JDI plans to combine HMO with JDI’s next-generation OLED technology to expand G6 wearable display production, with a sales target for this use case of c. JPY 25 billion in FY26/3 and JPY 50 billion in FY27/3.

HMO Development Costs

HMO builds upon JDI’s core capabilities in backplane technology built over many years. Thus, additional expenses required for HMO commercialization will be less than JPY 1 billion.

HMO Earnings Impact

While HMO will have minimal impact on JDI’s current FY22/3 consolidated earnings, JDI believes it will reinforce JDI’s global display technology leadership and drive JDI’s long-term, sustainable growth.

JDI will promptly disclose the details if matters requiring further disclosure arise.

文章来源:屏芯视界

欢迎关注:知识酷Pro