美国西北太平洋国家实验室(Pacific Northwest National Laboratory)以及奥勒冈州立大学(Oregon State University)的研究人员称,一种新研发的纳米级涂料能大幅提升半导体等器件的散热效率。

“在一种‘裸’铝基材的纳米结构化表面,我们观察到以10倍速改善的热传导系数(heat transfer coefficient);而在这些纳米结构化表面上也能量测到4倍速改善的临界热通量(critical heat flux)。”西北太平洋国家实验室的研究项目负责人Terry Hendricks表示;他是与澳乐高州立大学教授Chih-hung Chang一起进行上述研究的。

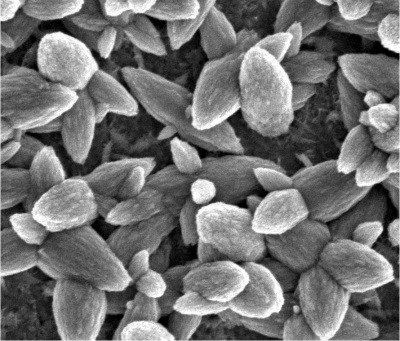

该种纳米涂布方法称为“微反应器辅助纳米材料沉积(microreactor assisted nanomaterial deposition,MAND)”,是将一种氧化锌微粒沉积在铝与铜基材上;有了纳米结构化的涂料加持,热传导就变得更有效率。研究人员表示,他们研发的涂布技术有助于先进激光器件、雷达或功率电子器件的散热,可应用在高性能计算机、军事航天、电动车或是再生能源系统。

研究人员指出,纳米级氧化锌涂料能让铜片的散热系数提升十倍

(来源:奥勒冈州立大学)

至于MAND技术的散热机制,目前则还在研究中,不过显然是因为高密度的成核点(nucleation sites)以及较佳的毛细现象(capillary pumping action),导致这些基材的每一表面积单位热传导效率有所改善。

若在采用微通道体系结构(microchannel architectures)的强制性液体冷却系统上应用,研究人员假定其技术能够在成核点密度之间开启一种关键折衷(tradeoff),让液体气泡的频率与气泡直径能被优化,使系统散热效能发挥到最大程度。

下一页:参考原文:Nano-coating cools chips four times faster,by R. Colin Johnson

《电子工程专辑》网站版权所有,谢绝转载

{pagination}

Nano-coating cools chips four times faster

by R. Colin Johnson

Nanoscale coatings could boost the efficiency with which heat can be removed from semiconductors and other devices, according to an Army Research Laboratory funded study by researchers at the Pacific Northwest National Laboratory (PNNL) and Oregon State University (OSU).

"A 10X improvement in heat transfer coefficient was observed for nanostructured surfaces over a 'bare' aluminum substrate. Further, an approximate 4X improvement in critical heat flux was also measured for these nanostructured surfaces," said the project leader at PNNL, Terry Hendricks. He performed the study with OSU professor Chih-hung Chang.

The nanoscale coating method, dubbed microreactor assisted nanomaterial deposition (MAND), deposited tiny grains of zinc oxide atop bulk aluminum and copper. As a result of the nanostructured coatings, heat was transfered far more efficiently. The researchers claim that their coating techniques will help in the cooling for advanced lasers, radars, and power electronics devices in applications including high performance computers, advanced military avionics, electric vehicles and energy recovery systems.

The mechanism used by MAND to remove the heat is still being investigated but appears to be cause by higher-density nucleation sites and better capillary pumping action, resulting in an improved heat-transfer surface-area per unit volume.

For forced liquid cooling systems using advanced microchannel architectures, the researchers hypothesize that their work exposes a critical tradeoff between nucleation site density, bubble frequency and bubble diameter that can be optimized for maximun heat dissipation.